Who we are and what we do

Blue Energy Solutions Australia are a team of experts, assisting large commercial and industrial energy users to think differently with the way they consume and convert energy.

Our goal is to reduce our clients carbon footprint through a range of innovative technologies and forward thinking solutions to meet Australia’s 2030 Carbon Emission Reduction Target

BESA’s key area of expertise is in the design, installation, commissioning and maintenance of:

- Biogas Power Generation and Flaring

- Cogeneration / Trigeneration Systems

- Industrial Automation and SCADA

- Remote Monitoring, Control and Data logging

- Operation & Maintenance

- Energy Efficiency Audits

Biogas Power Generation and Flaring

Biogas is created from waste resources and is generally classed as a renewable energy source. It can be produced from numerous feed stocks either in a Landfill, Digester or Covered Anaerobic Lagoon (CAL).

Industry’s where Biogas can be readily produced:

- Waste Management Facilities

- Waste Water Treatment Plants

- Abattoirs

- Food Processing and Manufacturing Plants

- Paper Mills & similar industry’s

- Farms & Agriculture

- Breweries & Distilleries

- Chemical and Pharmaceutical industry’s

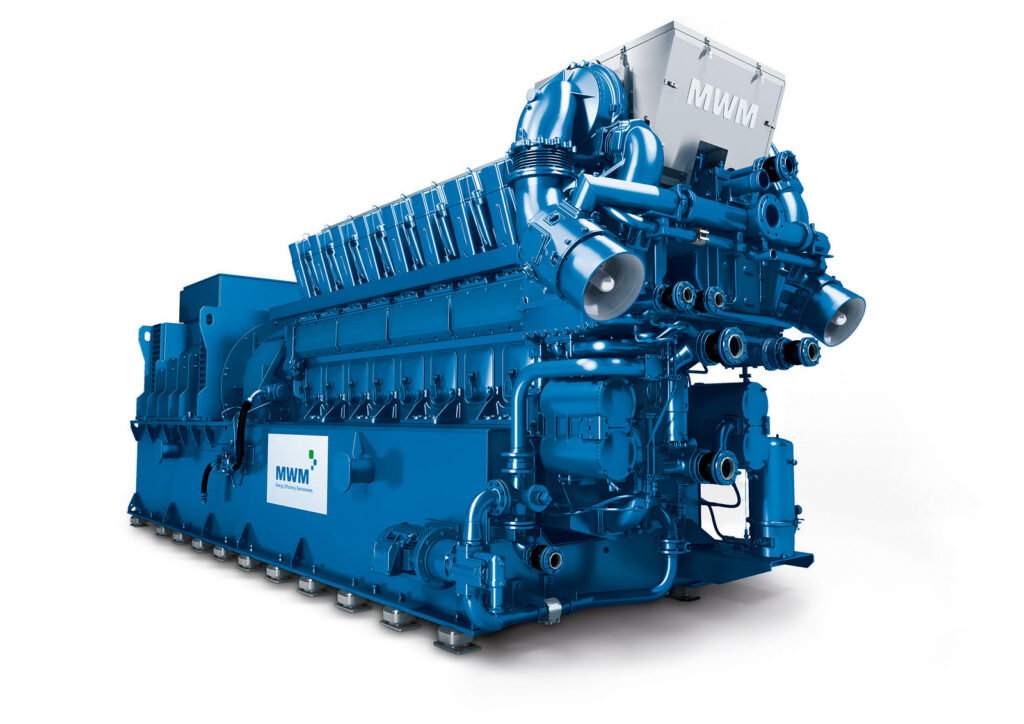

Once the gas is created it can then be extracted, processed and burnt in a gas generator to create power and heat for facility’s to offset power consumption and natural gas usage.

A typical biogas installation includes a biogas blower, chiller, flare, gas analyser and overseeing control system to automate the process and provide safe guards with handling flammable gasses.

BESA can provide a turnkey solution including initial feasibility studies, access to government funding and all related statutory applications required for grid connection of generators, hazardous area’s and local development approval.

Cogeneration and Trigeneration

Cogeneration is the simultaneous creation of power and heat from a fuel source, most commonly Natural Gas. Trigeneration is the added benefit of cooling through an absorption chiller.

Industry’s that benefit most from Cogeneration.

- Hospitals

- Food Processing and Manufacturing Plants

- Aquatic Centres

- Abattoirs

- Hotels and Commercial buildings

- High Power and Heat consuming Industries

A generator converts natural gas to electricity at 35-45% efficiency and emits 50%-60% less CO2 then typical grid supplied power. The heat generated from this process is also captured and used to further increase the systems efficiency by 30-40%.

This makes Cogeneration a great choice for industry’s that have a consistent use for power and heat and are looking to decrease their operational costs and carbon foot print.

If you think your facility or industry could benefit from Cogeneration or Trigeneration, contact us for a consultation.

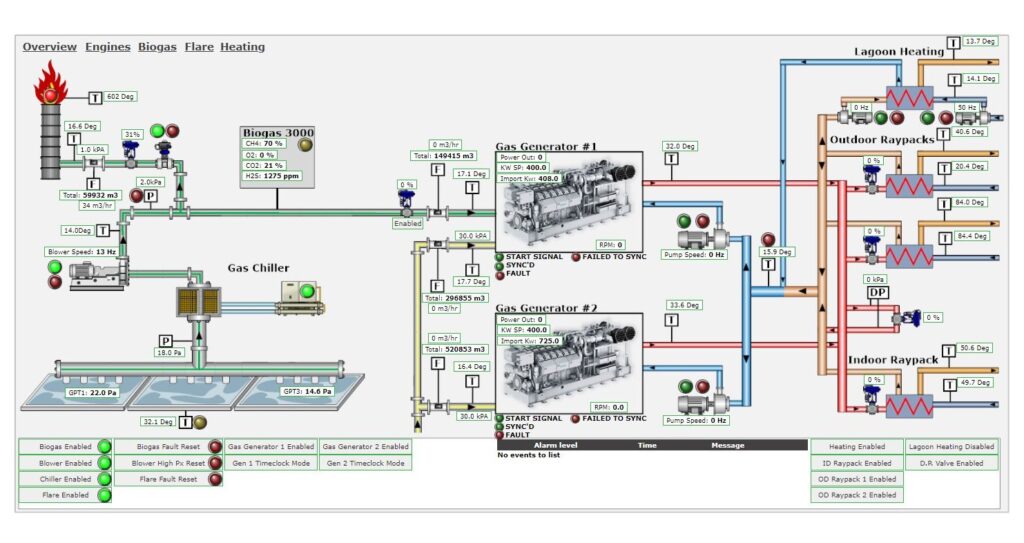

Industrial Automation and SCADA

BESA design and build bespoke Industrial Automation and SCADA (Supervisory, Control and Data Acquisition) systems for a wide range of applications including:

- Power Generation

- Cogeneration and Trigeneration

- Biogas Generation and Flaring

- Heating, Cooling and Pumping

- Hybrid Power installations

- Plant Control and Optimisation

A typical system involves a centralised PLC which processes inputs and delivers outputs based on programmable logic, remote I/O boards tailored to the application to extend the PLC’s control and a dedicated Server which hosts SCADA software giving users control and supervision of site to safely and efficiently operate.

Communication between the centralised PLC and devices can be hardwired or via Ethernet / Modbus TCP, RS-485 / Modbus RTU or CAN-Bus.

If you have a problem which requires a customised solution, contact us now for further information.